Recent years have seen an intense increase in the demand for packaging for the aseptic filling of products. This is confirmed by the report „Bag in Box Containers Market Analysis” and indicates that the cumulative increase in demand for aseptic packaging will amount to as much as 10.0% in the period from 2020 to 2027.

Apart from many known methods of food preservation, it is the method of aseptic filling of previously preserved food that gives high certainty for the microbiological and organoleptic safety of the product.

However, this method of packing and preserving food requires the use of highly burdensome methods of securing the packaging, including bag in box bags. The aseptic filling process is preceded by sterilization of the packaging with ionizing radiation. Most current pouring systems require the use of superheated steam (> 120oC) in order to prepare the package for opening in the filling chamber. The filling process is carried out in the presence of steam. After filling, the packaging, especially the collar and closure, are re-sterilized in order to be 100% sure that the process is aseptic.

Bag in box packaging, while ideal for storing aseptically filled products, is exposed to an increased risk of damage during the filling process.

As part of R&D works, we have developed a technology for the application of a protective layer, commonly known as neck band, which is designed to increase the durability and functionality of the packaging.

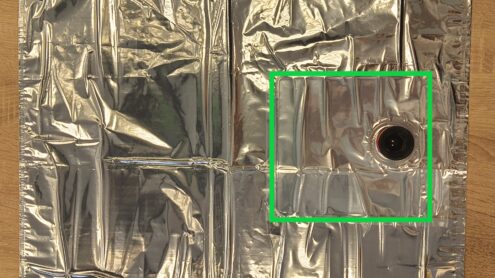

The bag in box collar is surrounded by a square of foil with dimensions of 100x100mm or 200x200mm. The specially designed structure of the foil is permanently heated to the outer foil and the collar. The role of this hood is to increase the dissipation of thermal energy around the collar. As a result, the effects of the degradation of the barrier foil are reduced. The risk of overheating the foil and the occurrence of the flex cracking effect is reduced, the stability of the oxygen barrier in this place is increased, the phenomenon of passivation of the aluminum layer is reduced, and the risk of tearing the collar out during pouring is also reduced.

The fully automated method of feeding the protective layer – neck band, during the production process and high-quality packaging for aseptic bottling, especially 220l bags, guarantee that the BIBP bag in box packaging will meet your quality and technological expectations.

Are you interested about the topic?

Please contact us:

We also invite you to our SM:

![]() www.facebook.com/producentbaginbox

www.facebook.com/producentbaginbox