Bag in Box in NFC Juice Production – Effective Pasteurization, Microbiological Safety, and Modern Packaging Solutions

Juice Season – a Key Moment for NFC Juice Producers

The juice-making season is a crucial period for producers of NFC (Not From Concentrate) juices. It begins with the harvest of hard fruits, primarily apples, and marks the start of a new production cycle. During this time, every stage of the process—from raw material selection and preparation, through optimization of technological processes, to the choice of packaging—has a decisive impact on the quality, shelf life, and appeal of the final product.

Producing NFC juices requires good practices, including careful fruit selection, adherence to high hygiene standards, and the right choice of packaging. It is equally important to preserve the quality of traditional flavors while developing unique blends that meet evolving consumer expectations.

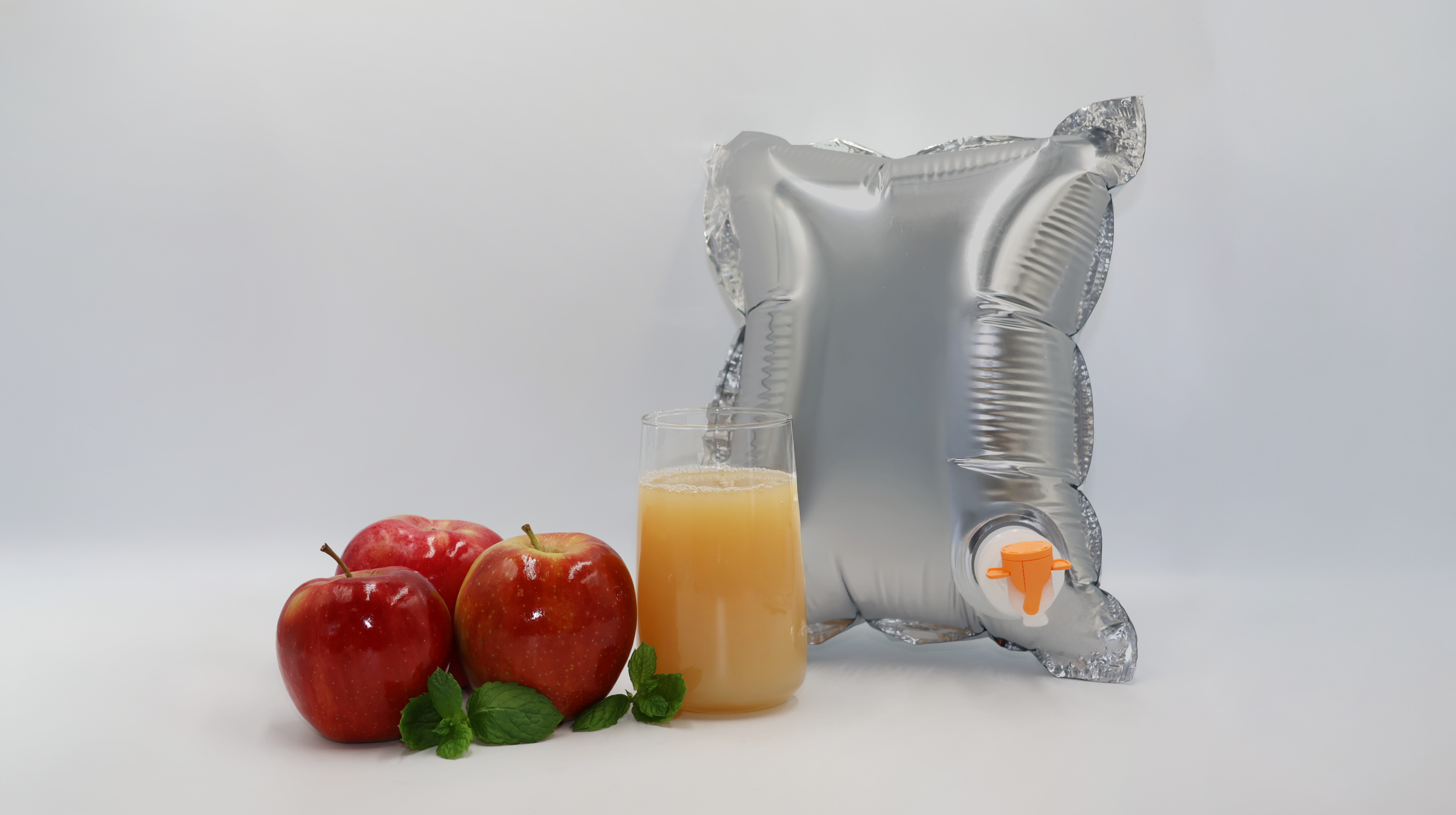

An increasingly popular solution is the Bag in Box system—a modern packaging technology that combines functionality, efficiency, and microbiological safety. These packages are adapted to the requirements of hot filling and ensure product durability, user convenience, and resistance to damage during transport and storage.

This article explores the key aspects of NFC juice production and packaging in Bag in Box systems, including pasteurization at around 80°C, sanitary requirements, raw material selection, packaging technical parameters, as well as market challenges such as e-commerce and short production runs.

- Good Manufacturing Practices (GMP) – the Foundation of Safe and Effective NFC Juice Production in Bag in Box

Safety and top quality in NFC juice production using Bag in Box are only possible through strict compliance with Good Manufacturing Practices (GMP). GMP is not just a set of formal requirements, but a rigorous hygiene and process control system aimed at eliminating microbiological and physicochemical risks at every production stage.

Key GMP elements include:

- Contamination risk management – designing the flow of raw materials and semi-finished products to prevent cross-contamination. Proper plant layout and process segregation are essential.

- Personnel and equipment hygiene – staff training, protective clothing, and CIP/SIP (cleaning-in-place, sterilization-in-place) systems ensure effective removal of contaminants and pathogens from machine surfaces.

- Documentation and monitoring of critical parameters – each stage is carefully recorded, with special attention to pasteurization parameters (temperature, time), which are decisive for microbiological stability.

- Traceability and batch tracking – labeling systems allow quick detection and withdrawal of defective batches, enhancing transparency and consumer safety.

Implementing GMP is the cornerstone of guaranteeing both the safety and quality of NFC juices in Bag in Box packaging.

- Raw Material Selection and Pasteurization Optimization (72–85 °C) – Preserving Natural Qualities and Microbiological Safety

Raw material quality is the most critical factor in producing premium NFC juices. Fruits must be ripe, healthy, and free from mechanical damage or disease. Prompt and proper processing after harvest directly influences juice quality.

Key steps include:

- Fruit selection – choosing fruit of appropriate quality, impacting flavor, aroma, and microbiological safety.

- Washing and sorting – removing dirt and pathogens to minimize contamination risks.

- Pasteurization at ~80°C – balancing effective microbial inactivation with minimal loss of vitamins, enzymes, and sensory qualities.

- Tailoring parameters to fruit types – apple, pear, and aronia juices differ in microbial profiles and require customized settings.

With precise raw material selection and optimized pasteurization, producers achieve juices that retain their natural character while meeting consumer expectations for freshness and safety.

- Choosing Bag in Box Packaging – Ensuring Safety and Durability in Hot Filling and Pasteurization

In NFC juice production, Bag in Box packaging must meet the specific demands of hot filling and storage, while providing one of the most practical and user-friendly solutions for transport and consumption.

Key technical requirements include:

- Thermal resistance – multilayer films (polyethylene, polyamide, EVOH) must maintain integrity at ~80°C.

- Oxygen barrier – special layers prevent oxidation, preserving nutrition and flavor.

- Seal integrity – strong, airtight seals prevent oxygen and microbial ingress.

- Durable taps and dispensers – designed to withstand high temperatures and repeated use, enhancing safety and convenience.

Properly engineered Bag in Box packaging ensures NFC juice is well-protected throughout production, distribution, and consumption.

- Microbiological Stability of NFC Juices in Bag in Box – How Technology Extends Freshness

Thanks to its design and properties, Bag in Box technology helps maintain high microbiological stability even after opening.

Advantages include:

- Minimal air contact – the collapsing bag reduces oxygen exposure and slows microbial growth.

- High oxygen barrier – EVOH laminates delay oxidation and quality loss.

- Hermetic closure – strong seals and taps prevent secondary contamination.

- Optimized pasteurization – ensures pathogen reduction while preserving sensory quality.

As a result, Bag in Box juices remain safe, fresh, and flavorful for weeks after opening—far longer than traditional packaging.

- Risks and Challenges in NFC Juice Production – Key Threats and Control Measures

Because they are not concentrated, NFC juices are particularly vulnerable to microbial and chemical threats that can reduce their quality and shelf life.

Main risks include:

- Microbiological contamination – yeasts, molds, and lactic acid bacteria causing fermentation, turbidity, or off-flavors.

- Oxidation – leading to vitamin C loss, discoloration, and flavor deterioration.

- Storage conditions – temperature fluctuations accelerate spoilage.

- Cross-contamination – insufficient sterility during filling can introduce pathogens.

To counter these risks, producers must implement HACCP systems and continuously monitor microbiological and physicochemical quality in accredited laboratories.

- Bag in Box for E-commerce and Contract Production – Flexibility and Functionality

The growth of online sales and the needs of small to medium producers demand packaging that is safe, convenient, and visually appealing.

Bag in Box advantages in this area:

- Short production runs – ideal for limited-edition flavors and quick production adjustments.

- Transport protection – sturdy cartons and durable bags minimize shipping damage.

- Ease of use – taps allow spill-free dispensing.

- Branding opportunities – full-color printed cartons stand out on the market.

- Extended freshness after opening – retaining taste and microbiological safety for longer.

This makes Bag in Box a first-choice solution for both contract manufacturers and brands selling directly online.

- Non-Standard Capacities – Flexibility in Modern Production

Beyond the standard 3–10 liter formats, the market now offers Bag in Box sizes tailored to different segments.

- 220-liter Bag in Box – large-format packaging for HoReCa, the food industry, and contract production. It enables safe, economical storage and transport while maintaining pasteurization standards.

These larger formats are ideal for seasonal surpluses, raw material storage, or extended production runs, where packaging durability and product safety are crucial.

Conclusion

Bag in Box technology in NFC juice production combines advanced material engineering and packaging design with rigorous production standards, including GMP and optimized pasteurization at ~80°C. Careful raw material selection, precise process control, and dedicated packaging ensure a high-quality product that meets both market and consumer demands.

With formats ranging from small, branded e-commerce packs to large 220-liter industrial bags, Bag in Box offers producers flexibility and efficiency in production and distribution—critical advantages during the intensive juice-making season.

As a result, Bag in Box remains one of the most efficient, safe, and consumer-friendly solutions in the NFC juice sector, combining convenience with the highest standards of quality and microbiological safety.