220 LITER BAG IN BOX BAGS

THE PERFECT SOLUTION FOR FRUIT AND VEGETABLE PROCESSING

There are a lot of fruit and vegetable processing companies on the Polish and international market. In Poland, it is estimated that it could be over 300 companies. These companies largely deal with the widely understood processing of fruit and vegetables into various components, such as concentrates, juices, nectars, pulp, jams and others. Fruit and vegetable raw materials are subjected to various technological processes, then preserved by thermal methods and poured into packaging. The question immediately arises, what packaging is ideally suited for storing such products?

There are a lot of fruit and vegetable processing companies on the Polish and international market. In Poland, it is estimated that it could be over 300 companies. These companies largely deal with the widely understood processing of fruit and vegetables into various components, such as concentrates, juices, nectars, pulp, jams and others. Fruit and vegetable raw materials are subjected to various technological processes, then preserved by thermal methods and poured into packaging. The question immediately arises, what packaging is ideally suited for storing such products?

Among the many types of packaging available on the market, BAG IN BOX with a capacity of 220 liters are becoming increasingly popular. This is due to a number of their features and properties, among others favorable price-to-volume ratio and value of the stored product, hygiene of use and guarantee of quality and safety of use. Thanks to the low weight of the packaging and reduction of waste management costs by up to 90%, these products are environmentally friendly.

Manufacturers choose the packaging based on the product stored in it and the available machinery park, thanks to which it is possible to fill the packaging. Thus, they meet all the requirements of the target customer.

Currently, there are two main 220L bags standards on the Polish and foreign market, which take into account the barrier properties of plastics. Material barrier means its ability to limit the amount of vapor and gas permeability. There are 220L bags, so-called high barrier (HB) and bags with a standard barrier (STD).

HB and STD bags can be filled using the technology:

- aseptic filling

- hot filling

A single 220L bag is made of a number of properly selected raw materials, each of which has specific functions. The inside of the bag is made of LLDPE type foil with very good welding and mechanical properties. They enable the formation of durable peripheral seals, which protects the packaging against tearing and deformation. On the other hand, the outer foil is a material with barrier properties, effectively protecting the packaging against uncontrolled migration of gases from the environment or from inside the packaging. This ensures that the product’s organoleptic properties, i.e. taste, aroma and freshness, are maintained. The second important feature of the outer films is ensuring the desired mechanical properties of the packaging, i.e. resistance to cracking, tearing and deformation. This allows you to cope with high loads that arise when it spills up to 250 liters of fluids of different densities.

There are 2 groups of materials for the outer shell of 220L bags

- coextruded foils with EVOH functional barrier (transparent) – mainly adapted for hot-filling products and for freezing.

- laminated foils with a barrier based on metalized PET – a thermal film sealing process is used for the production of laminated film. It guarantees high foil strength. An additional advantage of this film is that it 100% cuts off the flow of light into the bag.

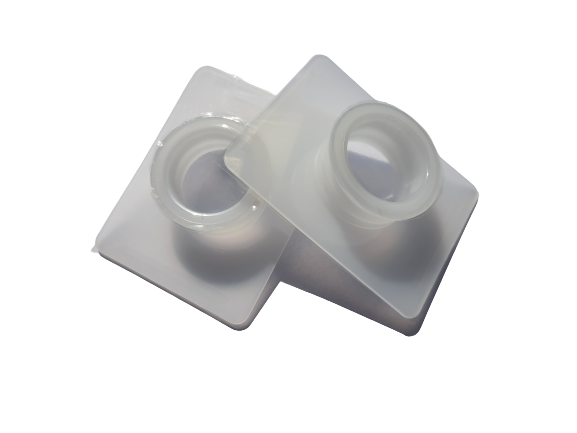

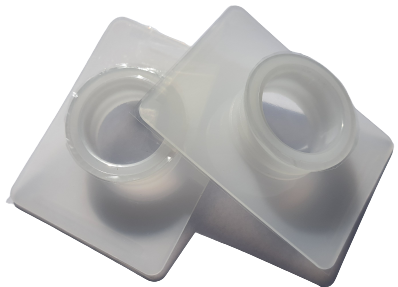

Flanges are an integral part of the 220L bag. A popular standard is the 1 “flange with a plug. The common name of this closure – ELPO, comes from the name of the Italian company that proposed this solution as one of the first in the 80’s. Currently, the standard 1 “flanges (so-called ELPO) and the pouring machine heads adapted to them are common. The 1 “flange is characterized by very low thermal expansion and high thermal resistance (especially during combined sterilization of the flange). Both the flange and the plug are delivered in a closed position. This guarantees complete asepticity of such packaging. In addition, depending on the type of machine that spills the product, these flanges come in two forms: one-ring and two-ring. In addition to standard flanges, we also make bag in box with specialized types of closures, which are dedicated to a specific technological line and product filling process.

The outer dimensions of the bag are chosen so that they can be freely arranged both in a standard 250 liter barrel and in a cardboard barrel (octabine).

At the Research and Development Center of BIBP Sp. z o.o. a detailed comparative analysis was carried out of the 220 liter bag in box packaging available on the Polish market. Strengths and weaknesses of the offered packaging were determined using various measuring and analytical techniques. Then, the data collected from these analyzes were used to develop with our suppliers the best raw materials for the production of such components, so that the packaging we offer meet their requirements. At the same time, we aim to continuous improvement of used raw materials and technological solutions.

The process of developing bag in box packaging began in our company in 2014 and it is still being improved. After hundreds of experiments, research and consumer tests, we can clearly state that our products are of the highest quality and meet the expectations of end users. We have developed a fully repeatable and reproducible production process, which means that the highest standards of supervision are maintained at both the raw material supply stage, ongoing production, quality control and sterilization. The control covers, among others, temperature, quality of peripheral and flange seals, foil strength and lamination strength, friction coefficient and film thickness are tested. Periodically, drop tests and micro-crack tests are also carried out using the Gelbo Test method.

hundreds of experiments, research and consumer tests, we can clearly state that our products are of the highest quality and meet the expectations of end users. We have developed a fully repeatable and reproducible production process, which means that the highest standards of supervision are maintained at both the raw material supply stage, ongoing production, quality control and sterilization. The control covers, among others, temperature, quality of peripheral and flange seals, foil strength and lamination strength, friction coefficient and film thickness are tested. Periodically, drop tests and micro-crack tests are also carried out using the Gelbo Test method.

The whole production process is covered by a qualitative monitoring using the PN ISO 2859-1 standard and maintaining the highest hygiene and safety standards under the BRC Packaging v 6. standard. The 220L bag can be directly used for filling a range of products with high density, concentration and low water activity. We recommend storing products in them that are spilled after pasteurization or will be frozen at later stages of processing. The company BIBP Sp. z o.o. also provides bags fully adapted for spilling under aseptic conditions.

The types of foods that can be found in such packaging are almost limitless. Our bags are used in packaging not only domestic fruit and vegetable processing products, but also in the process of packaging citrus (orange juice and concentrate, lemon juice and others) and tropical (mango, papaya, kiwi, guava, pineapple). The raw materials selected at the design stage ensure that products packed in bags with very low acidity, high content of coloring pigments and high enzymatic activity can be safely poured and transported even between different continents and geographical zones. Our packaging can also be used to store products such as chokeberry (juice, concentrate), blueberry or red wine.

The high level of production hygiene and the validated radiation sterilization process guarantee that also vegetable products such as carrots, parsley, celery and potato can be safely stored in our 220L packaging. The table below presents the recommended combinations of a given type of food product and a specific type of 220L bag.

Last but not least, the possibility of storing dairy products in them, which require not only filling under aseptic conditions but also freezing.

|

BIBP 220L PREMIUM |

BIBP 220L ECONOMY |

BIBP 220L HOT FILLING |

BIBP 220L FROZEN |

| HIGH BARRIER |

STANDARD BARRIER |

STANDARD BARRIER |

STANDARD BARRIER |

| METALIZED |

METALIZED |

TRANSPARENT |

TRANSPARENT |

| ASEPTIC FILLING |

ASEPTIC FILLING |

HOT FILLING |

FOR REFRIGERATED DISTRIBUTION |

| PET/MET + EVOH + LLDPE |

PET/MET + LLDPE |

EVOH + LLDPE |

EVOH/EVA + LLDPE |

| TOMATO |

|

|

|

|

| CONCENTRATE |

|

best choice |

allowed |

allowed |

| DICED |

allowed |

best choice |

allowed |

|

| SAUCE |

allowed |

best choice |

allowed |

|

| TRADITIONAL FRUIT |

|

|

|

|

| APPLES |

allowed |

best choice |

allowed |

allowed |

| APRICOT |

allowed |

best choice |

|

|

| PEACH |

allowed |

best choice |

|

|

| GRAPES |

allowed |

best choice |

allowed |

|

| PEAR |

allowed |

best choice |

allowed |

|

| TROPICAL FRUITS |

|

|

|

|

| BANANA |

best choice |

|

|

|

| GUAVA |

best choice |

|

|

|

| KIWI |

best choice |

|

|

|

| MANGO |

best choice |

|

|

|

| PINEAPPLE |

best choice |

|

|

|

| PASSION FRUIT |

best choice |

|

|

|

| PAPAYA |

best choice |

|

|

|

| CITRUS FRUIT |

best choice |

|

|

|

| CARROT |

best choice |

allowed |

allowed |

|

| BERRIES |

best choice |

allowed |

|

|

| DAIRY |

allowed |

best choice |

allowed |

allowed |

BIBP sp.z o.o. having a stable product for the most demanding customers of the sector, wanting to still develop, it is constantly working on expanding the offer of 220L bags. Recently, she completed work on packaging, which replaced the commonly used metallized PET laminate, a special material that further reduces the cost of waste management and makes the 220L metallized bag fully recyclable. Companies interested in this solution are welcome to contact us.

To sum up, the 220L bag in box, designed and manufactured entirely by the polish company, is a response to the growing demand for this type of packaging. Thus, it meets the highest standards on the international market. This is reflected in the opinions of our clients – leaders in the fruit and vegetable processing industry – who continually entrust us with all their production. For us as a company where customer needs are always put first, it is a reason for great satisfaction and motivation, which leads to continuous development and improvement.

To be up to date with our activities and get to know us even better, follow our social media:

www.facebook.com/producentbaginbox

www.facebook.com/producentbaginbox

www.linkedin.com/company/bag-in-box-poland

www.linkedin.com/company/bag-in-box-poland

necessary and should be something natural. It is with great pleasure that, as part of the

necessary and should be something natural. It is with great pleasure that, as part of the Christmas campaign, we organized a fundraiser for the Municipal Shelter for Homeless Animals in Bielsko Biała. The collection lasted 4 weeks with us, during this time we manage to collect specialized dry and wet food, cleaning products, collars, lashes, blankets and lairs, everything that is most needed in a shelter. The joy of the animals and their owners was the best for us 🙂

Christmas campaign, we organized a fundraiser for the Municipal Shelter for Homeless Animals in Bielsko Biała. The collection lasted 4 weeks with us, during this time we manage to collect specialized dry and wet food, cleaning products, collars, lashes, blankets and lairs, everything that is most needed in a shelter. The joy of the animals and their owners was the best for us 🙂

components that meet the requirements of the market. The selection of materials takes into account the preservation of strength parameters measured by tests: flex cracking, drop test, burst test, etc. Great attention is paid to the stability of raw materials during the entire life cycle of the product (also when filled), through the use of aging tests, mechanical degradation, and microscopic analysis. It is important whether the packaging is subject to the ADR convention and if so, the design process takes into account the stringent requirements for this type of packaging. It is also worth mentioning a number of valves and taps compatible with the bag in box, thanks to which the dosing of the product is accurate, fast and safe, which is a key feature when dealing with products presenting a potential risk. Access to a wide base of suppliers gives extensive possibilities in the selection of taps and closures, depending on the density, viscosity and properties of a given product and the method of its dosing desired by the customer.

components that meet the requirements of the market. The selection of materials takes into account the preservation of strength parameters measured by tests: flex cracking, drop test, burst test, etc. Great attention is paid to the stability of raw materials during the entire life cycle of the product (also when filled), through the use of aging tests, mechanical degradation, and microscopic analysis. It is important whether the packaging is subject to the ADR convention and if so, the design process takes into account the stringent requirements for this type of packaging. It is also worth mentioning a number of valves and taps compatible with the bag in box, thanks to which the dosing of the product is accurate, fast and safe, which is a key feature when dealing with products presenting a potential risk. Access to a wide base of suppliers gives extensive possibilities in the selection of taps and closures, depending on the density, viscosity and properties of a given product and the method of its dosing desired by the customer. Bag in box closures allow for easy and problem-free dosing of the product, thus there is no excessive draining or sticking of the medium. It is also related to the fact that during use there is no risk of air or any contaminants getting inside the packaging, therefore the product does not foam and does not splash. Another factor influencing performance is the fact that the bag’s flexible material allows its contents to be almost completely emptied. This is not possible when using standard containers, often of fancy shape, where a large amount of product is wasted and thrown away by being left inside. From a broader perspective, also the transport and storage in a bag in box are much more efficient. The shape of the cuboid as represented by the bag in box minimizes the so-called dead space, whether in a warehouse or on a pallet, and at the same time maximizes the transport capacity. On the other hand, empty, used packages are folded practically flat, so even after using the product, they do not take up unnecessary space.

Bag in box closures allow for easy and problem-free dosing of the product, thus there is no excessive draining or sticking of the medium. It is also related to the fact that during use there is no risk of air or any contaminants getting inside the packaging, therefore the product does not foam and does not splash. Another factor influencing performance is the fact that the bag’s flexible material allows its contents to be almost completely emptied. This is not possible when using standard containers, often of fancy shape, where a large amount of product is wasted and thrown away by being left inside. From a broader perspective, also the transport and storage in a bag in box are much more efficient. The shape of the cuboid as represented by the bag in box minimizes the so-called dead space, whether in a warehouse or on a pallet, and at the same time maximizes the transport capacity. On the other hand, empty, used packages are folded practically flat, so even after using the product, they do not take up unnecessary space.

For a long time our production has been carried out in the Ultra Clean standard. CLEAN ROOM is a place where environmental parameters are controlled, thanks to which an adequate low concentration of solid pollutants in the air is ensured. Continuous filtration of the air inside makes the bag-in-box produced in this standard ideal for storing products that are poured aseptically or after the pasteurization process. The interior of such a room is filled with air, which is forced through a special system of HEPA filters that eliminate any fractions of pollutants. Employees who want to get to the room are obliged to go through the airlock and be dressed in special protective suits, additionally they are also equipped with masks, gloves and shoe covers.

For a long time our production has been carried out in the Ultra Clean standard. CLEAN ROOM is a place where environmental parameters are controlled, thanks to which an adequate low concentration of solid pollutants in the air is ensured. Continuous filtration of the air inside makes the bag-in-box produced in this standard ideal for storing products that are poured aseptically or after the pasteurization process. The interior of such a room is filled with air, which is forced through a special system of HEPA filters that eliminate any fractions of pollutants. Employees who want to get to the room are obliged to go through the airlock and be dressed in special protective suits, additionally they are also equipped with masks, gloves and shoe covers.

There are a lot of fruit and vegetable processing companies on the Polish and international market. In Poland, it is estimated that it could be over 300 companies. These companies largely deal with the widely understood processing of fruit and vegetables into various components, such as concentrates, juices, nectars, pulp, jams and others. Fruit and vegetable raw materials are subjected to various technological processes, then preserved by thermal methods and poured into packaging. The question immediately arises, what packaging is ideally suited for storing such products?

There are a lot of fruit and vegetable processing companies on the Polish and international market. In Poland, it is estimated that it could be over 300 companies. These companies largely deal with the widely understood processing of fruit and vegetables into various components, such as concentrates, juices, nectars, pulp, jams and others. Fruit and vegetable raw materials are subjected to various technological processes, then preserved by thermal methods and poured into packaging. The question immediately arises, what packaging is ideally suited for storing such products?

hundreds of experiments, research and consumer tests, we can clearly state that our products are of the highest quality and meet the expectations of end users. We have developed a fully repeatable and reproducible production process, which means that the highest standards of supervision are maintained at both the raw material supply stage, ongoing production, quality control and sterilization. The control covers, among others, temperature, quality of peripheral and flange seals, foil strength and lamination strength, friction coefficient and film thickness are tested. Periodically, drop tests and micro-crack tests are also carried out using the Gelbo Test method.

hundreds of experiments, research and consumer tests, we can clearly state that our products are of the highest quality and meet the expectations of end users. We have developed a fully repeatable and reproducible production process, which means that the highest standards of supervision are maintained at both the raw material supply stage, ongoing production, quality control and sterilization. The control covers, among others, temperature, quality of peripheral and flange seals, foil strength and lamination strength, friction coefficient and film thickness are tested. Periodically, drop tests and micro-crack tests are also carried out using the Gelbo Test method.