Currently, there are many variants on the flexible bag in box packaging market in terms of structure and types of film used in the production process. One of the two most popular are packaging made of either a barrier film based on ethylene copolymer and vinyl alcohol (EVOH foils) or a laminate based on metallized polyethylene terephthalate (Met-PET foils).

EVOH-based films are highly flexible and highly resistant to cracking. From an aesthetic point of view, this foil is usually transparent. One of the main properties of the EVOH film is its barrier to atmospheric gases (nitrogen, oxygen and carbon dioxide). Barrier is a parameter that determines the permeability of gases through a given material. The appropriate level of foil barrier ensures that the packaging will be suitable for storing, among others food products, thus extending their shelf life. The limited migration of gases into the interior and from the packaging guarantees the desired organoleptic qualities of the stored products. The limited access of oxygen delays the aging process and effectively blocks the growth of microorganisms in the product. The current technological possibilities allow for a wide range of modifications in the composition and structure of EVOH foil, towards a significant increase in the barrier to gases, strength and color of the foil itself.

oxygen and carbon dioxide). Barrier is a parameter that determines the permeability of gases through a given material. The appropriate level of foil barrier ensures that the packaging will be suitable for storing, among others food products, thus extending their shelf life. The limited migration of gases into the interior and from the packaging guarantees the desired organoleptic qualities of the stored products. The limited access of oxygen delays the aging process and effectively blocks the growth of microorganisms in the product. The current technological possibilities allow for a wide range of modifications in the composition and structure of EVOH foil, towards a significant increase in the barrier to gases, strength and color of the foil itself.

In turn, the laminated foil based on metallized PET, apart from similar gas permeability properties to EVOH foil, is  characterized by a barrier to light radiation (especially UV). This is important when the stored product is particularly prone to aging under the influence of UV and requires additional protection against light. Met-PET film is often used by customers who fill in aseptic conditions, because the thermal sterilization process in the area of the collar in bags made of Met-PET film is more efficient (slower degradation of the film). At present, the production process of EVOH film and functional additives allows the available types of EVOH film to compete with Met-PET film. Thus it is possible to produce packaging that meets the requirements of aseptic filling and thermal sterilization. Additionally, unit carton is a common method of storing filled bags. This type of outer packaging ensures complete lack of light access at every stage of the logistics process.

characterized by a barrier to light radiation (especially UV). This is important when the stored product is particularly prone to aging under the influence of UV and requires additional protection against light. Met-PET film is often used by customers who fill in aseptic conditions, because the thermal sterilization process in the area of the collar in bags made of Met-PET film is more efficient (slower degradation of the film). At present, the production process of EVOH film and functional additives allows the available types of EVOH film to compete with Met-PET film. Thus it is possible to produce packaging that meets the requirements of aseptic filling and thermal sterilization. Additionally, unit carton is a common method of storing filled bags. This type of outer packaging ensures complete lack of light access at every stage of the logistics process.

So which foil should you choose?

Functionality.

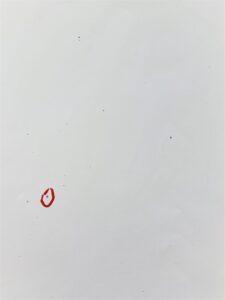

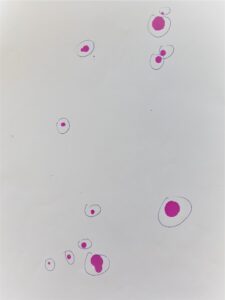

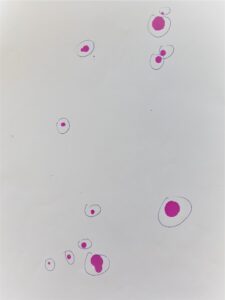

One of the key parameters in assessing the suitability of the packaging for storage purposes is its barrier properties, which can be ensured by the use of an appropriate carrier such as EVOH, Met-PET and many others. In laboratory conditions, it is possible to determine the barrier level of a given package with high accuracy. However, in reality, the production (filling, packaging), logistic (storage and storage conditions, transport, distribution) and technical operations (treatment by the target customer, storage conditions, etc.) significantly affect the durability and functionality of the packaging. Years of experience and tests carried out in laboratory conditions (transport tests and simulations with the use of vibration methods) have proved significant differences in the durability of packaging made of EVOH film compared to Met-PET film. In particular, we are talking about the number of generated microdamages, which significantly affect the deterioration of foil mechanics (foil strength) and worsen the barrier properties of the package. One of the methods of testing the susceptibility of film and entire packaging to durability throughout the distribution process is the Gelbo method. It consists in cyclic twisting a sheet of foil through an angle of 460 °. The foil sheets treated in this way are then checked for the number of microdamages or the level of oxygen permeability (OTR). Below we present the results of our tests carried out on EVOH film and Met-PET film. The samples were subjected to 900 cycles and examined for the number of microdamages.

operations (treatment by the target customer, storage conditions, etc.) significantly affect the durability and functionality of the packaging. Years of experience and tests carried out in laboratory conditions (transport tests and simulations with the use of vibration methods) have proved significant differences in the durability of packaging made of EVOH film compared to Met-PET film. In particular, we are talking about the number of generated microdamages, which significantly affect the deterioration of foil mechanics (foil strength) and worsen the barrier properties of the package. One of the methods of testing the susceptibility of film and entire packaging to durability throughout the distribution process is the Gelbo method. It consists in cyclic twisting a sheet of foil through an angle of 460 °. The foil sheets treated in this way are then checked for the number of microdamages or the level of oxygen permeability (OTR). Below we present the results of our tests carried out on EVOH film and Met-PET film. The samples were subjected to 900 cycles and examined for the number of microdamages.

EVOH FOIL MET-PET FOIL

Analyzing the above results, it can be concluded that the number of microcracks in the EVOH film is much lower than in the case of Met-PET film. Thus, it is confirmed by the argument that EVOH film can, under certain conditions, successfully replace Met-PET film.

Ecology.

Another important factor in choosing the right packaging is its possible environmental impact. Especially now, when  there is a growing awareness of users about the fate of used packaging, the method of recovering secondary raw materials or potential environmental fees (e.g. the fee for extended producer responsibility). Based on the recommendations of the RecyClass group, we can conclude that flexible packaging made of Met-PET film will be classified as low compatibility (D-E-F) due to the difficult process of post treatment towards obtaining secondary raw materials. At the same time, packaging based on EVOH film (classified as limited capatibility C-D), can in most cases be further processed to recover, among others, polyethylene (LDPE).

there is a growing awareness of users about the fate of used packaging, the method of recovering secondary raw materials or potential environmental fees (e.g. the fee for extended producer responsibility). Based on the recommendations of the RecyClass group, we can conclude that flexible packaging made of Met-PET film will be classified as low compatibility (D-E-F) due to the difficult process of post treatment towards obtaining secondary raw materials. At the same time, packaging based on EVOH film (classified as limited capatibility C-D), can in most cases be further processed to recover, among others, polyethylene (LDPE).

Based on our experience and the collected knowledge, increasingly bag in box packaging made of Met-PET film is converted into packaging made of EVOH film while maintaining full functionality and durability of the packaging.

Are you interested about the topic?

Please contact us:

https://bibp.pl/kontakt/

We also invite you to our SM:

www.facebook.com/producentbaginbox

www.facebook.com/producentbaginbox

www.linkedin.com/company/bag-in-box-poland

www.linkedin.com/company/bag-in-box-poland

www.youtube.com/channel/UCwTohfEU1aqHrJxSeW4Pz-Q/featured

www.youtube.com/channel/UCwTohfEU1aqHrJxSeW4Pz-Q/featured

oxygen and carbon dioxide). Barrier is a parameter that determines the permeability of gases through a given material. The appropriate level of foil barrier ensures that the packaging will be suitable for storing, among others food products, thus extending their shelf life. The limited migration of gases into the interior and from the packaging guarantees the desired organoleptic qualities of the stored products. The limited access of oxygen delays the aging process and effectively blocks the growth of microorganisms in the product. The current technological possibilities allow for a wide range of modifications in the composition and structure of EVOH foil, towards a significant increase in the barrier to gases, strength and color of the foil itself.

oxygen and carbon dioxide). Barrier is a parameter that determines the permeability of gases through a given material. The appropriate level of foil barrier ensures that the packaging will be suitable for storing, among others food products, thus extending their shelf life. The limited migration of gases into the interior and from the packaging guarantees the desired organoleptic qualities of the stored products. The limited access of oxygen delays the aging process and effectively blocks the growth of microorganisms in the product. The current technological possibilities allow for a wide range of modifications in the composition and structure of EVOH foil, towards a significant increase in the barrier to gases, strength and color of the foil itself. characterized by a barrier to light radiation (especially UV). This is important when the stored product is particularly prone to aging under the influence of UV and requires additional protection against light.

characterized by a barrier to light radiation (especially UV). This is important when the stored product is particularly prone to aging under the influence of UV and requires additional protection against light.  operations (treatment by the target customer, storage conditions, etc.) significantly affect the durability and functionality of the packaging. Years of experience and tests carried out in laboratory conditions (transport tests and simulations with the use of vibration methods) have proved significant differences in the durability of packaging made of EVOH film compared to Met-PET film. In particular, we are talking about the number of generated microdamages, which significantly affect the deterioration of foil mechanics (foil strength) and worsen the barrier properties of the package. One of the methods of testing the susceptibility of film and entire packaging to durability throughout the distribution process is the Gelbo method. It consists in cyclic twisting a sheet of foil through an angle of 460 °. The foil sheets treated in this way are then checked for the number of microdamages or the level of oxygen permeability (OTR). Below we present the results of our tests carried out on EVOH film and Met-PET film. The samples were subjected to 900 cycles and examined for the number of microdamages.

operations (treatment by the target customer, storage conditions, etc.) significantly affect the durability and functionality of the packaging. Years of experience and tests carried out in laboratory conditions (transport tests and simulations with the use of vibration methods) have proved significant differences in the durability of packaging made of EVOH film compared to Met-PET film. In particular, we are talking about the number of generated microdamages, which significantly affect the deterioration of foil mechanics (foil strength) and worsen the barrier properties of the package. One of the methods of testing the susceptibility of film and entire packaging to durability throughout the distribution process is the Gelbo method. It consists in cyclic twisting a sheet of foil through an angle of 460 °. The foil sheets treated in this way are then checked for the number of microdamages or the level of oxygen permeability (OTR). Below we present the results of our tests carried out on EVOH film and Met-PET film. The samples were subjected to 900 cycles and examined for the number of microdamages.

there is a growing awareness of users about the fate of used packaging, the method of recovering secondary raw materials or potential environmental fees (e.g. the fee for extended producer responsibility). Based on the recommendations of the RecyClass group, we can conclude that flexible packaging made of Met-PET film will be classified as low compatibility (D-E-F) due to the difficult process of post treatment towards obtaining secondary raw materials. At the same time, packaging based on EVOH film (classified as limited capatibility C-D), can in most cases be further processed to recover, among others, polyethylene (LDPE).

there is a growing awareness of users about the fate of used packaging, the method of recovering secondary raw materials or potential environmental fees (e.g. the fee for extended producer responsibility). Based on the recommendations of the RecyClass group, we can conclude that flexible packaging made of Met-PET film will be classified as low compatibility (D-E-F) due to the difficult process of post treatment towards obtaining secondary raw materials. At the same time, packaging based on EVOH film (classified as limited capatibility C-D), can in most cases be further processed to recover, among others, polyethylene (LDPE).